Multiple Rip Saw

MRS-155

Tags :

Multiple

Heavy duty

HEAVY DUTY Multiple Rip Saw

Extra Robust 100 HP motor

Great Cutting Thickness of 155 mm (6.1")

Continuous duty 100 HP arbor motor allows deep cutting speeds of thick lumber

Main Features

- MRS-155 has a massive cast iron base, composing the majority of total machine weight of 2700KG.

- This design provides incredible absorption characteristics under deep cutting, especially while performing thick lumber ripping with a multi-blade set up.

- Precision chain and rails(dip chain) system facilitates accurate cutting operations.

Specification

| MRS-155 | |

|---|---|

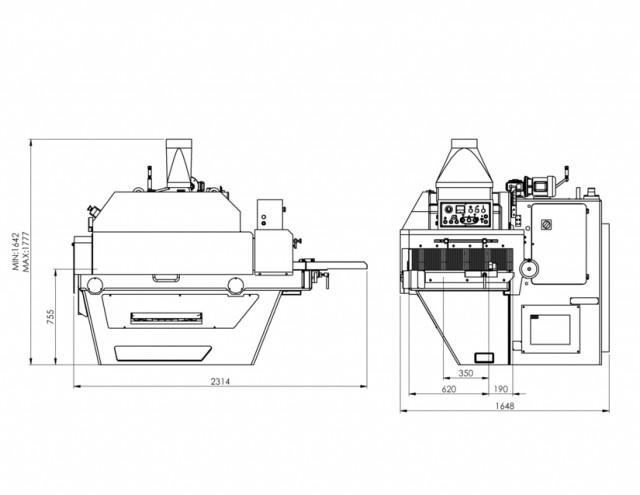

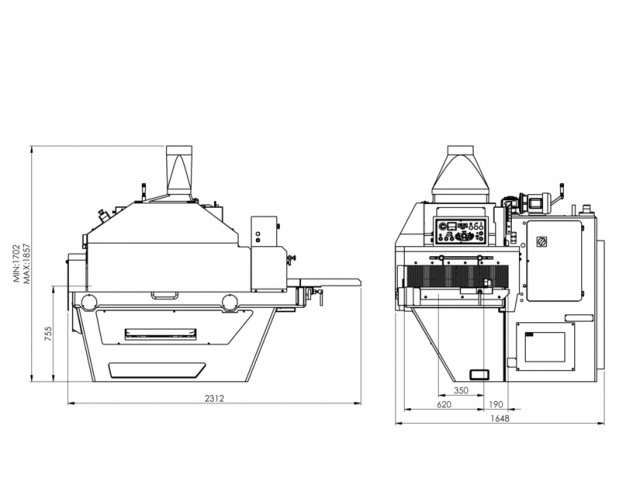

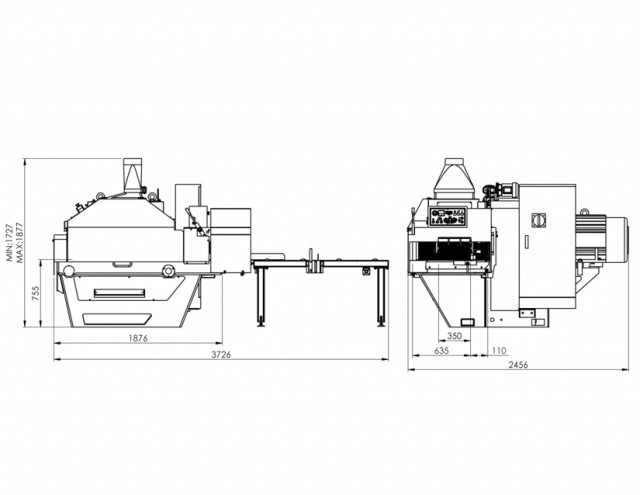

| Max. cutting thickness | 155 mm |

| Max. citting width | 350 mm |

| Distance from column to link chain center | 380 mm |

| Mini. working length | 700 mm |

| Max. sawblade diameter | Ø450 mm (18") |

| Mini. sawblade diameter | Ø355 mm (14") |

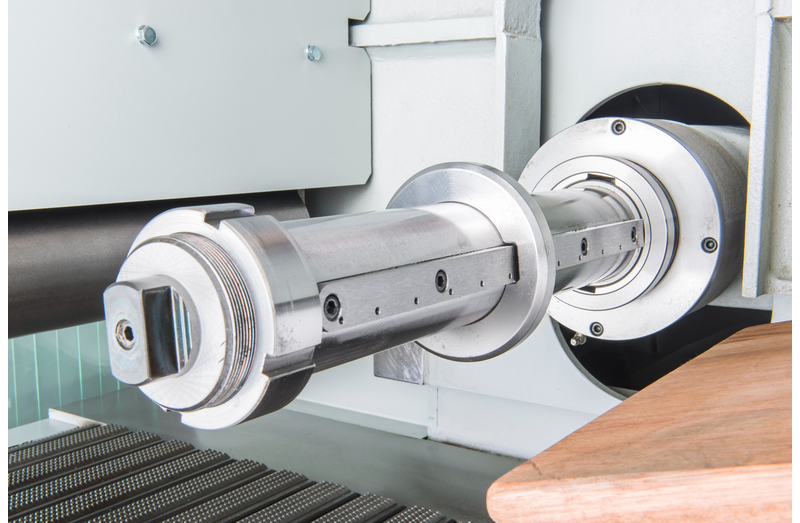

| Saw blade bore | Ø70 mm (12") |

| Saw arbor diameter | Ø55 mm (8") |

| Saw arbor speed | 3000 r.p.m(14"~16" Saw Blade) / 2500 r.p.m(16"~18" Saw Blade) |

| Saw arbor motor | 75 HP or 100 HP |

| Feed motor | 3 HP |

| Variable feed speeed | 2.5~24 M/min |

| Hold down roller elevating moter | 1 HP |

*We reserve the right to amend any of the above specifications without prior notice.

Comparison

*We reserve the right to amend any of the above specifications without prior notice.