Cross-cut Saw

CFS-100

Tags :

Cross-cut

Semi Optimizing Cross-cut Saw

Cut-Off Saw Series 100

Designed for finger-jointed lumber production or wood preparations of anterior stage.

Main Features

- Provides 3~5 times higher production rate than manual cut-off saws.

- Save more than 5% of wood material for finger-jointed lumber production.

- Stable NC system provides long life time. Customers are all giving good reputations.

- Icon guided operating on a Colored Touch Screen. Easy recognized and operating.

- CE approved by German TÜV that protects safety of the operator.

Features of Cut-Off Saw

- Economical optimizing saw cutting and High production

- Ideal for finger jointing (for defect) materials and mass material preparation.

- Comprehensive safety guards for maximum operator protection.

- The machine has a compact footprint and user-friendly design.

- The controller adopts an industrial-grade computer that employs a 32-bit floating-point DSP system. It features flash and battery backup SRAM for double security. Superior to conventional PC-based controls, it can fully eliminate the machine going down or being damaged due to a poor environment, such as, unstable voltage, high temperature, sawdust, etc.

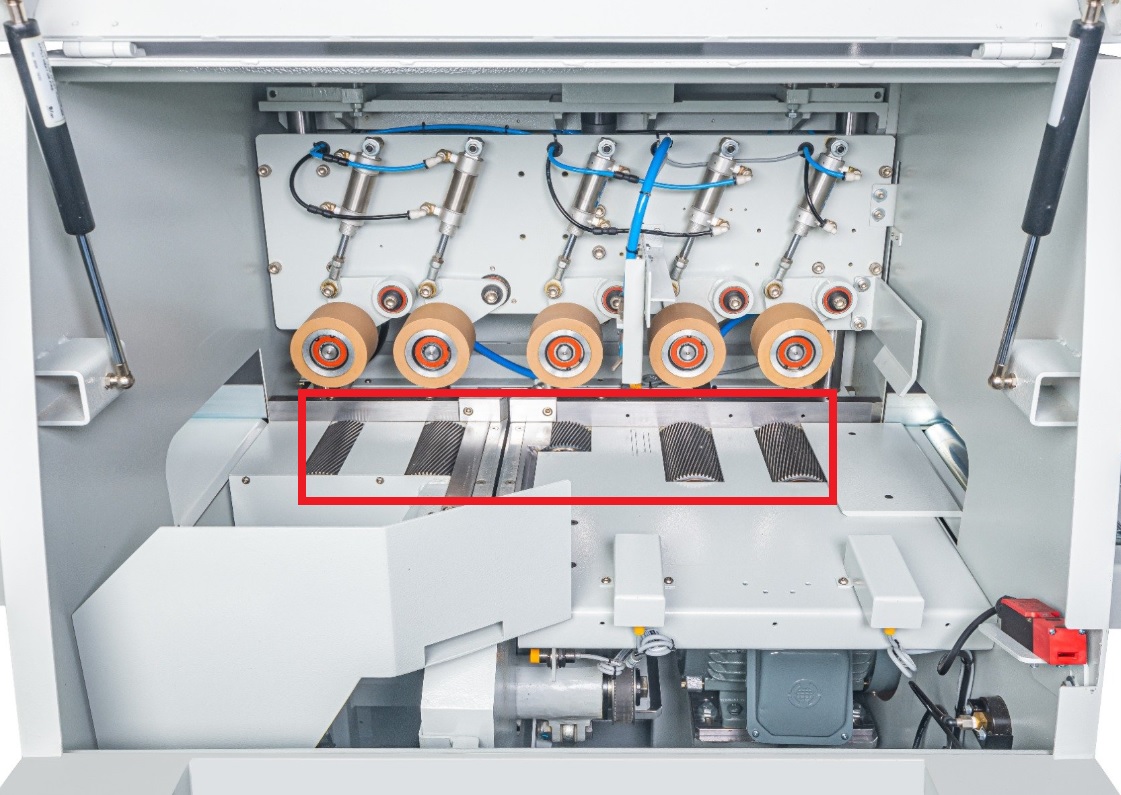

- Defect blowing system combined with computerized logic control permits the blowing time and the length of defect to be set as desired. This feature provides efficient defect removal, which avoids defects bumping against the saw blade, resulting in the machine going down or saw blade damage.

- The computer control provides easy and fast maintenance.

- Feed is driven by a servomotor for fast and accurate motions.

Specification

| CFS-100 | |

|---|---|

| Saw arbor motor | 10 HP |

| Feed motor | 2 kW |

| Saw arbor speed | 3400 r.p.m. |

| Variable feed speeed | 80 M/min |

| Max. sawblade diameter | 455 mm (18") |

| Saw blade bore | Ø30 mm |

| Table height (H) | 900 mm |

| Minimum feeding material | 300 mm |

| Maximum table load | 25 kgs |

| Air compressed (Consumption) | 7~9 kg/cm2 (160 M3/hr) |

| Diameter of dust collector inlet | Ø100 mm x 2 |

| Net weight | 900 kgs |

*We reserve the right to amend any of the above specifications without prior notice.

Comparison

| Traditional machine | CFS-100 | CFS-200A | |

|---|---|---|---|

| Cutting speed | 45 times/min | 80 times/min | 150 times/min |

| Feedrate | N/A | 80 M/min | 150 M/min |

| Productivity | 1600 M/8 hours | 6400 M/8 hours | 8000 M/8 hours |

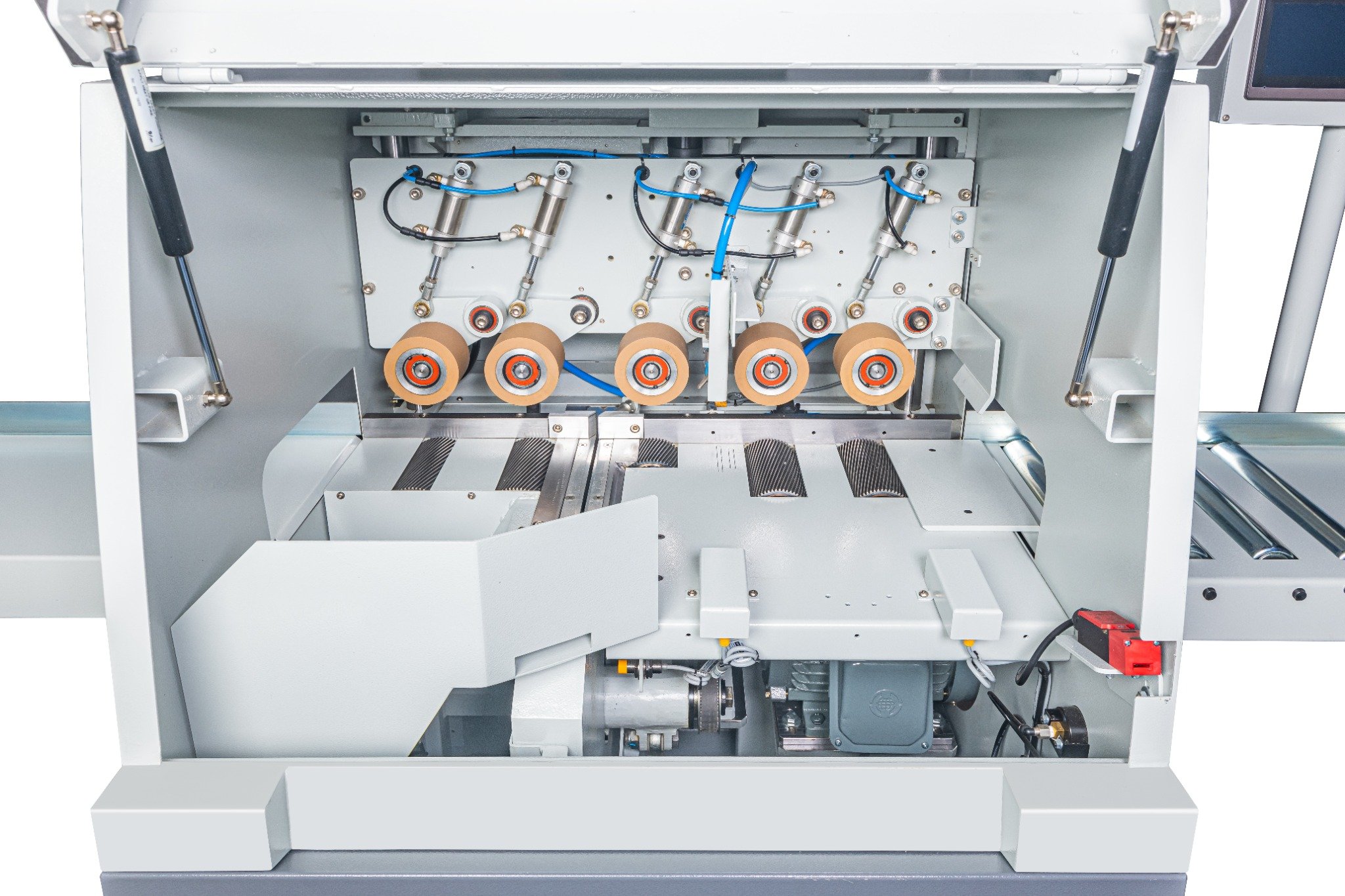

| No of rollers | N/A | 5 pieces | 7 pieces |

| Max. table load | N/A | 25 kgs | 40 kgs |

| Feed motor | N/A | 2 Kw (TECO) | 3.5 Kw (Mitsubishi ) |

| Maximum circular saw dia. | N/A | 455 mm (18") | 540 mm (21") |

| Machine weight | N/A | 900 kgs | 1250 kgs |

| Material's limitation | N/A | Length under 4M is suggested | Applicable for 4M and above |

*Remark: "Productivity" varies on factors such as "material length", "cutting length" and "operation conditions" etc.