Introducing the All-New CFS-100 Series

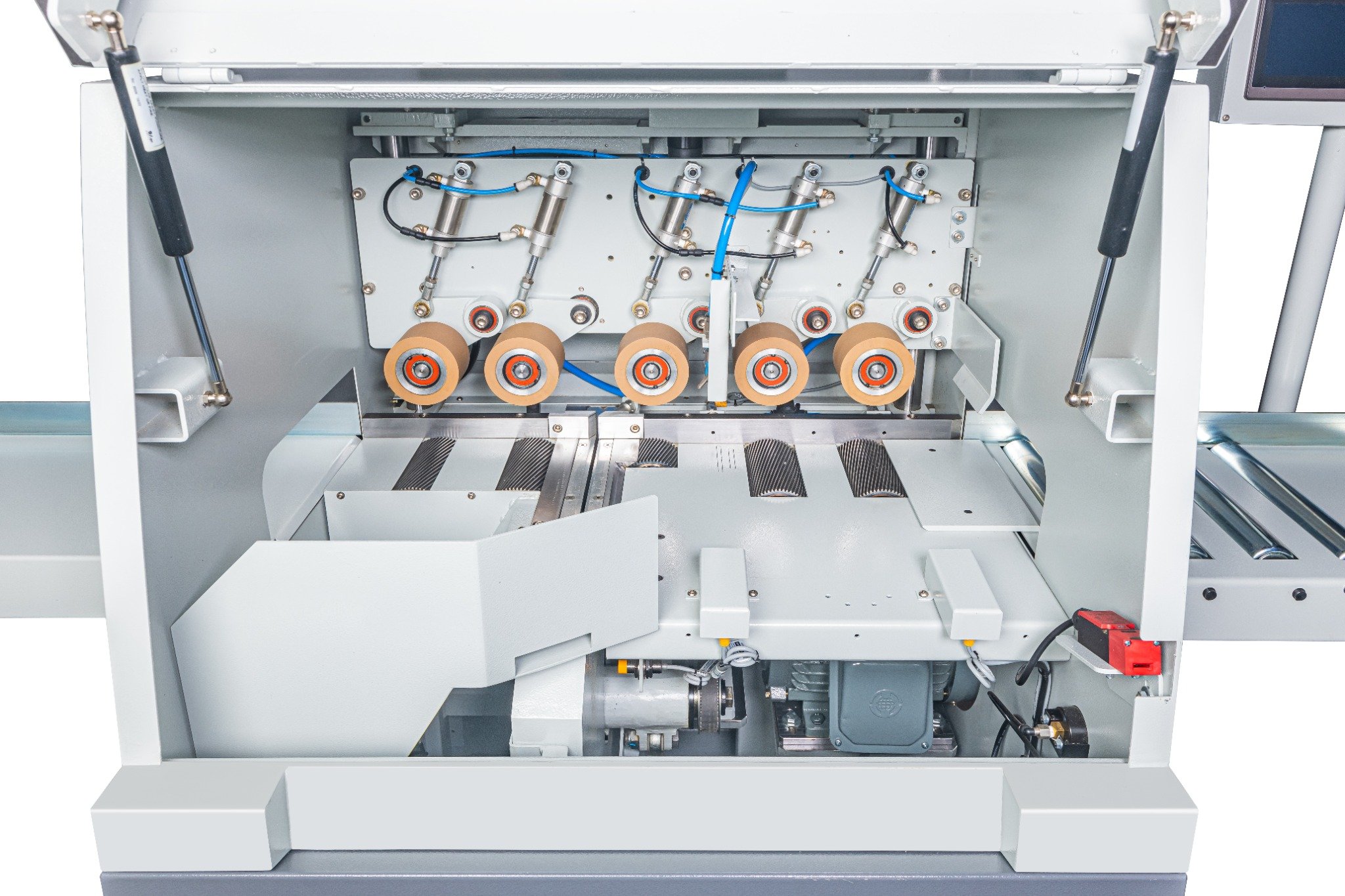

New vs. Previous Design Comparison

Previous Design

All-New Upgraded Design

Key Advantages

30% Larger Viewing Window – Clearer Operation View and Enhanced Safety

The viewing window has been enlarged by 30%, allowing operators to clearly observe the machine's internal operation. This design helps monitor cutting status and detect any abnormalities in real-time, reducing human error and improving overall safety.

7.5 kg Lighter Saw Arbor Housing – Reduced Vibration and Enhanced Precision

The redesigned aluminum saw arbor housing reduces weight by 7.5 kg, minimizing vibrations during operation. This results in improved cutting stability and precision, particularly beneficial for high-speed processing lines.

Front-Side Roller Height Adjustment – Safer and More Convenient Operation

The roller height adjustment mechanism is positioned at the front of the machine, eliminating the need to move to the rear or side for settings. This user-friendly design enhances operator safety and significantly reduces setup time, improving overall work efficiency.

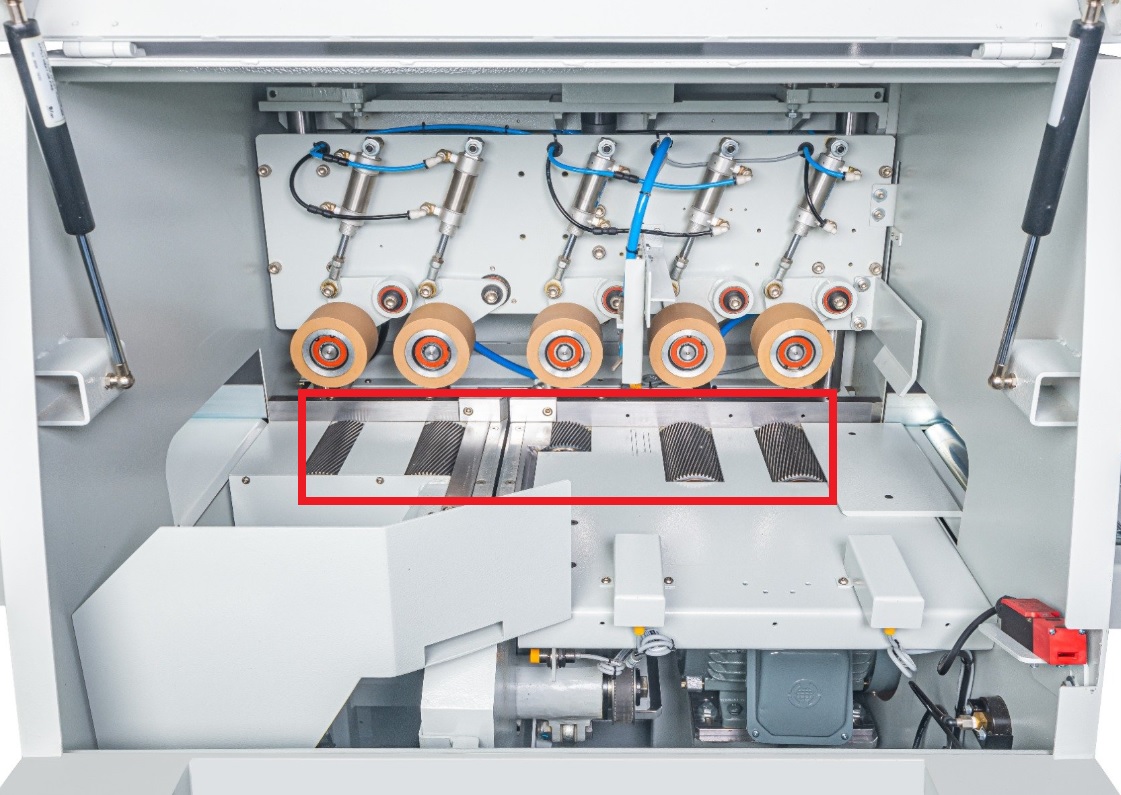

Widened Pressure Roller – Improved Feeding Stability

The pressure roller has been redesigned with a wider profile, providing more consistent and stable contact with the material. This helps prevent slipping and ensures smoother feeding even on longer or heavier workpieces.